How to Do Quality Control in Bulk Trail Camera Orders

B2B buyers should pay close attention to the quality assurance processes of their chosen bulk trail camera supplier. In this article, we’ll break down the key quality control practices in bulk trail camera orders, from pre-production design to post-delivery support.

Stage 1: Pre-Production Quality Planning

To effectively measure quality control, you need to establish very clear parameters. The materials for which you need to set parameters include the sensors, lenses, and housings.

In order to set quality parameters for a device, you need to perform the waterproofing, motion testing, detection testing, and night vision testing of the prototype surveillance cameras.

Design Validation is key to testing the prototype trail cameras for their waterproofing, motion detection accuracy and night vision clarity. Regarding OEM/ODM projects it is very important to have detailed specifications covering image resolution, trigger speed, battery type and connectivity.

At WOSPORTS, every OEM/ODM order starts with a Join Technical Review, aligning our engineering team with client specifications before mass production begins.

Stage 2: Quality Control in Production

Continuous inspections throughout the manufacturing process guarantee that each unit satisfies the same exacting standards:

Inspections of assembly lines: Confirming proper component integration at every turn.

Testing of the Sample: Random units are put through tests for waterproofing, trigger speed, and detection range.

Error Prevention Systems: Automated notifications spot discrepancies before they become serious.

Stage 3: Testing the Final Product

Before we ship anything, we put each batch through tests that mimic how people will actually use them. Here’s what we check:

Environmental Stress: We leave units in really hot, cold, humid, and dusty places.

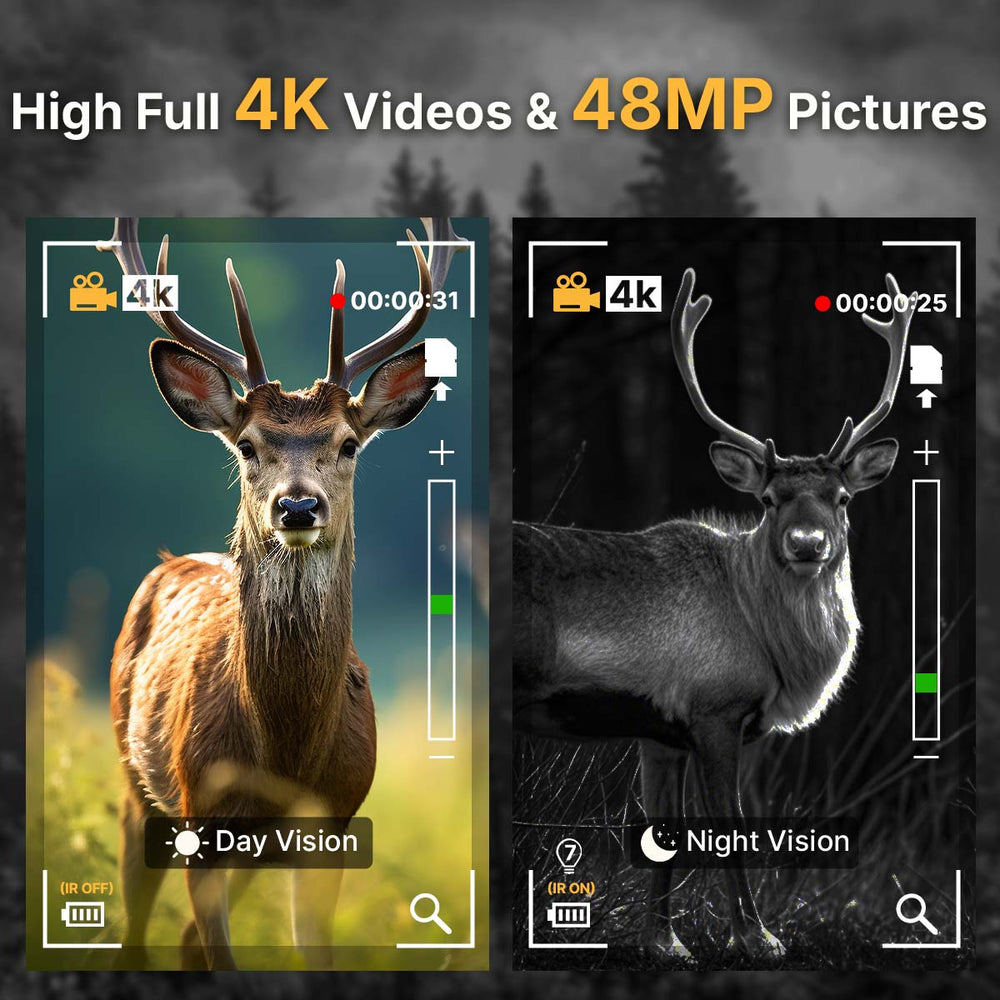

Performance: We look at how well the motion sensors work, how far they can detect movement, and how clear the night vision is.

Battery & Power: We make sure everything works with regular AA batteries, lithium packs, or solar power.

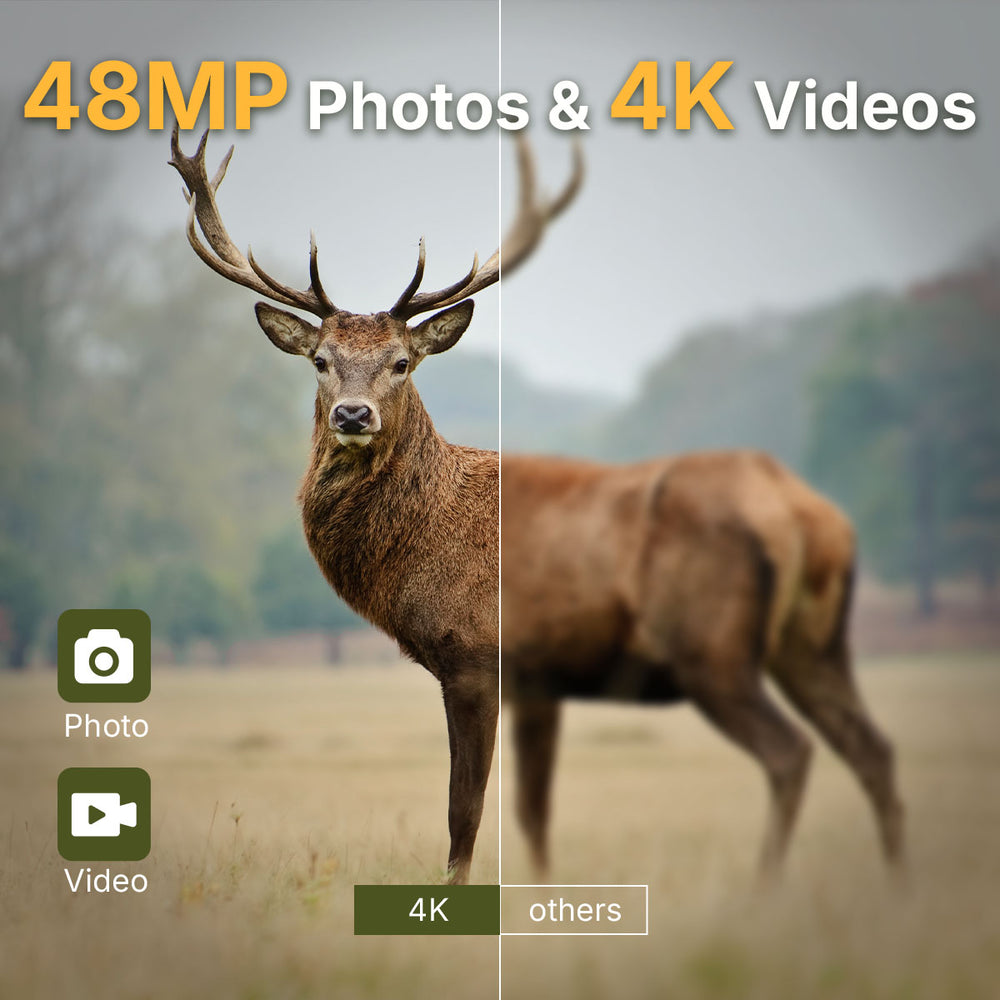

Image/Video: We check the resolution, frame rates, and how clear the videos and photos are, especially when it's dark.

For example, the WOSPORTS Wildlife Trail Cameras undergo a 72-hour durability test to confirm consistent operation before bulk shipment.

Stage 4: Pre-shipment inspection and packaging

Bulk shipments need to be able to survive storage and transit:

Cameras are shielded from physical harm during transportation by shock-proof packaging.

Verifying CE, FCC, and RoHS certifications through compliance checks.

WOSPORTS wholesale project provides pre-shipment sample approval, ensuring that customers are satisfied with the bulk shipment.

Stage 5: Post-Delivery Quality Assurance

Even after delivery, QC continues with monitoring and feedback collection:

Warranty Policies – Reliable suppliers provide warranties covering manufacturing defects.

After-Sales Support – Technical teams should assist with troubleshooting.

Feedback Integration – Field data from distributors and end-users helps improve next production runs.

Common Quality Issues in Trail Cameras

False Triggers – Poor PIR calibration can cause unwanted activations.

Blurry Night Images – Low-quality IR sensors lead to unclear wildlife footage.

Short Battery Life – Inconsistent power systems reduce field reliability.

Water Leakage – Weak casing seals cause internal damage.

Connectivity Failures – In cellular models, poor antenna integration affects performance.

Search

Popular Posts

Recent Posts

Nov 28, 2024

Troubleshooting Common Trail Camera Issues

Jan 10, 2025

Why Does My Trail Camera Stop Working at Night?